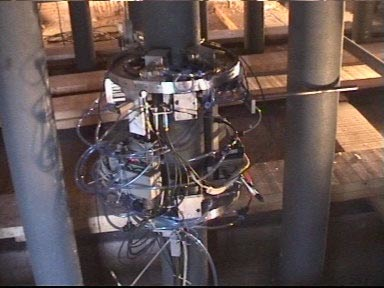

Technique is an automated robotic crawler to aid ultrasonic inspection of reformer tubes. It provides a tabular and interactive digital output. The Technique can simultaneously collect the tube data such as ultrasonic dB level of attenuation, diameter of tube and bowing angle at every location. An interactive, graphical user interface is part of digital report along with conventional hardcopy print in tabular format.

Reformer Tube Inspection System Advantages are as follows:

The method follows same technique of manual ultrasound coupling and hence it is industry wide proven for the intended inspection. A macro level view of overall tubes condition in the reformer is also reported, emphasizing troublesome areas / corner of furnace, if any. The outcome of inspection becomes more systematic and traceable with point- wise reading on each tube for ultrasound attenuation and creep strain. It avoids the need for scaffolding requirement and saves tube inspection time and helps achieving reduction in shutdown time of plant. Automation deploys limited water source for coupling and nearly eliminates need for overhead water drum arrangement which overcomes additional issues related to drum filling, vacuum water clogging, etc.