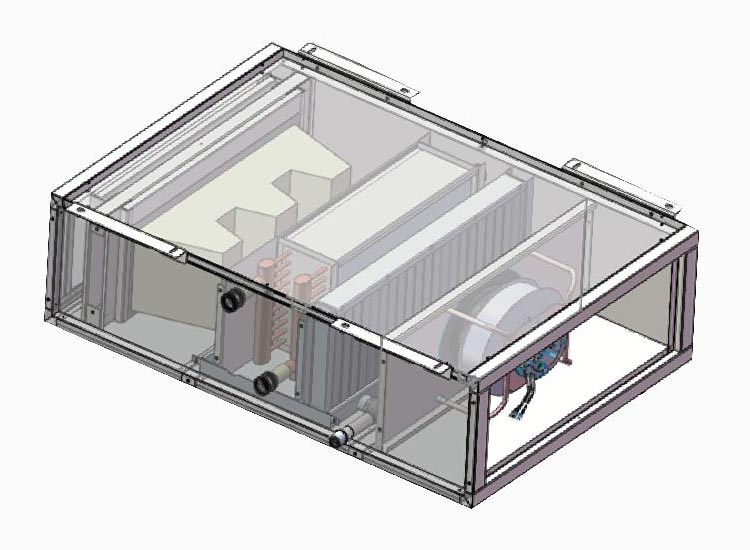

Some specific features of these products include Panels with double skins with thickness 25 and 43 millimeter with PUF’s that is free from HFC and CFC with density of 40 Kg/Cum

Features:

- To prepare base frames of these products, we use galvanized stainless steels with thickness of 1.4 millimeter at least

- One has an option of selecting chilled, hot, direct expanding and steam coils in these units

- Base frame of heavy G.I (Galvanized steel sheet) channel of min thickness 1.4 mm with lifting holes for handling.

- Centrifugal fans used by art of DIDW Forward/Backward curved Or Aerofoil AMCA Certified generally of makes. All fans are statically and dynamically balanced

- Common base frame for Motor and Blower.

- Coil section are provided with choice of chilled water, direct expansion, hot water and steam coils with 2, 4, 6 & 8 rows deep. Imported copper tube is used in fabrication of coil for better heat transfer.

- To maintain the drainage system of condensates aluminium and G.I. steel sheets are used

- For mixing returning and fresh air mixing chambers are designed in these products

- Induction motors with squirrel cage and power range of 50/60 cycle, 415+10% volts are provided with AC supply in 1 phase

- Primary and secondary filter units are available in these units

- RAL coloured AHU are available in different standards

- For easy use and to meet specific demands as per application needs accessories provided includes spray type humidifier, Finned strip heater, pan type humidifier, HRW (heat Recovery Wheel) and VFD

- Material Steel / Stainless Steel Asbestos Cement Fiberglass

- Surface Treatment Coated Film Coated Embossed

- Water Proof Tamper Proof Corrosion Resistant.